Your requirements – our possibilities

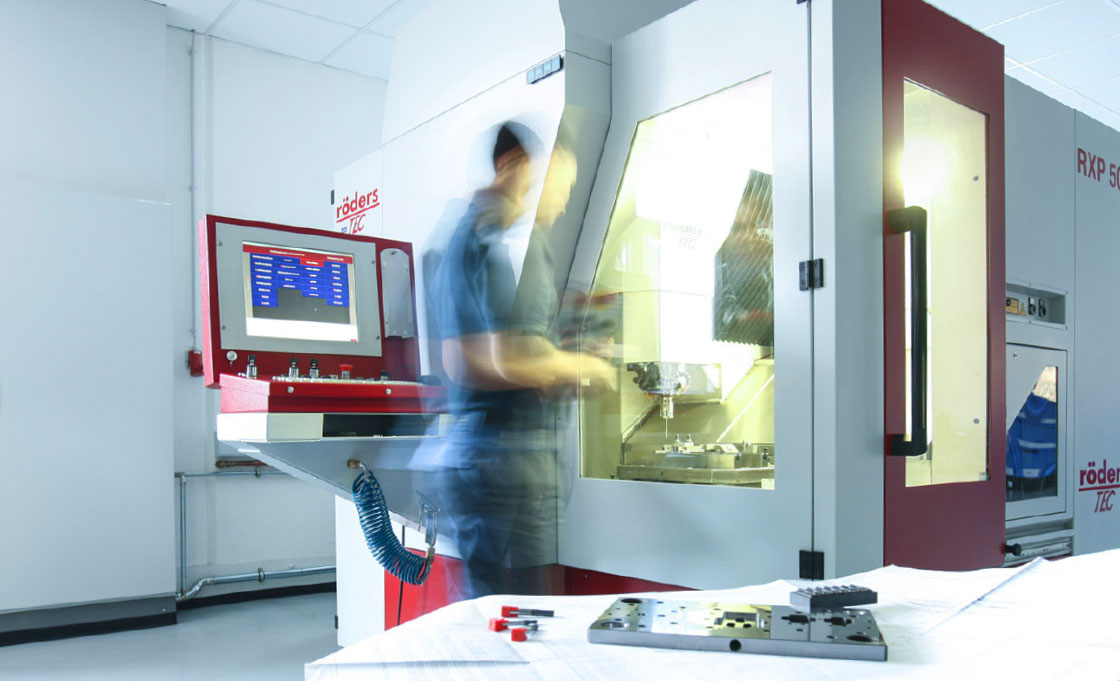

Do benefit from our pool of machinery – also in form of an extended workbench.

We produce on the basis of your drawings and specifications or we develop, jointly with you, your ideas from their introduction into production right up to the finished product.

You will benefit from the skills and resources of our design department and in the field of die making. Hölzel manufactures mechanical components from the minimum number of 1 up to medium-sized series either as single units or parts completely fitted into assemblies.

Use our die making capacities also for contract work. Apart from that, we can produce spare parts for your stamping dies in accordance with the drawings provided.

When it comes to complementing our techniques by heat treatment and electroplating, we can count on the long-standing cooperation with our reliable supplier base.

We process high-alloy tool steel, carbide and ceramic as well as all kinds of non-ferritic and ferritic metals for sheet metal processing.

The degree of accuracy achieved with the relevant surface quality is better than 0.002 mm.

At a glance:

- optical profile grinding

- jig grinding

- creep feed grinding

- flat grinding

- cylindrical grinding

- wire-cut EDM

- die sinking

- HSC milling, hard milling, turning

- micro shot blasting, polishing

- laser marking